The Loctite Design Guide for Bonding Plastics Volume 62. With 5000 plus patents Loctite leads the category and.

Loctite Plastics Bonding System Plastic Glue Super Glue Glue

You are not alone.

. The Loctite Design Guide for Bonding Plastics Volume 6 Block Shear Test Method Moisture Cure Products 1Assemblies were tested on an Instron 4204 mechanical properties tester equipped with a 50 kN load cell and a pull speed of 005 per minute. 3M Scotch-Weld Epoxy Adhesive. Each method is associated with equipment labor and other costs that you most consider.

There are four essential techniques for bonding plastic components. An informational resource for anyone looking to bond plastics this completely updated 96-page guide provides detailed technical information on the. It is critical that this joint is well sealed to prevent fluids such as blood or medicine from leaking.

In one form or another. Barry Kostyk who conducts bonding seminars for practicing engineers and students when hes not busy overseeing some of the largest adhesive. These fasteners may be molded into place.

A wide variety of adhesive technologies are available to meet the bonding needs of manufacturers. The stress is located at one end of the bond line. Hot Melt Adhesives 8.

The Problem The Loctite Design Guide for Bonding Plastics Volume 6 2 Plastics have become an integral part of everyday life. For 50 plus years Loctite has delivered customers with innovative sealing and adhesive solutions. Many engineers dont know how to use adhesives properly laments Dr.

It would be difficult to identify a manufacturing process which does not use plastics in one form or another. Plastics have become an integral part of everyday life. It is also essential that the position of the cannula remains fixed.

With detailed information on adhesive types joint design and substrates this guide offers the. The Loctite Design Guide for Bonding Plastics provides bond strength data for 30 substrates including ABS delrin nylon polycarbonate polypropylene polyethylene and PVC. In bonding plastic feathers and nocks onto arrow shafts 3M Scotch-Weld Industrial Plastic Adhesive dries quickly to a firm bond that resists plasticisers and water.

The top performing adhesives used for the structural bonding of plastics fall into three main adhesive categories. Loctites continuous commitment to improvement insures constant progress of frustration-free dispensing systems and breakthrough formulations. Check adhesive for compatibility with the plastic.

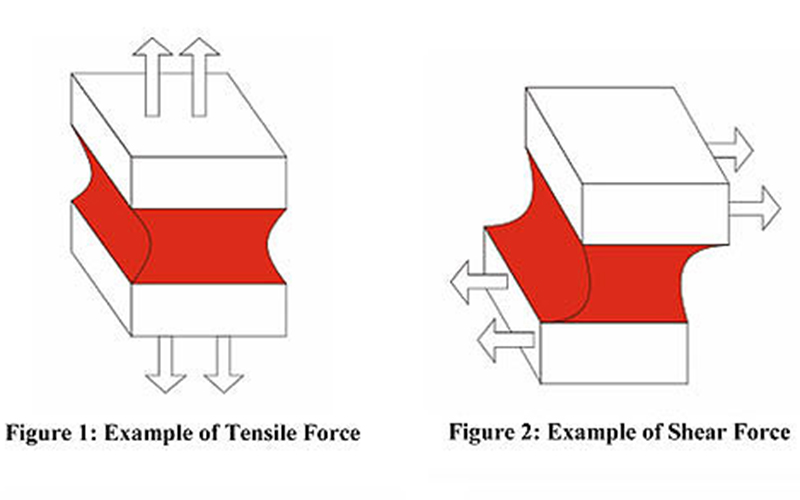

6 The Loctite Design Guide for Bonding Rubber and TPEs Volume 3 Maximize ShearMinimize Peel and Cleavage. For thin bondlines in automotive interior trim attachment 3M Quick Bonding. The guide also presents shear strength data on 23 Loctite adhesives including cyanoacrylates epoxies hot melts light cure acrylics polyurethanes silicones and no.

Difficult to identify a manufacturing process which does not use plastics. Whereas in the case of shear both ends of the bond resist the stress. Design Guide for Bonding Plastics Volume 5 How To Use The Plastic Bonding Guide Chapters Adhesive Shear Strength Table For a detailed explanation of the information contained in the Adhesive Shear Strength table please turn to the next page.

Light Curing Acrylic Adhesives 9. Description Of Adhesives 6. Even products which appear to be composed exclusively of metals are usually coated sealed or adhesively joined using polymeric materials.

This bonding guide is aimed at design en gineers and technicians who have the task of joining together todays most advanced materials. 1 Mechanical Fastening Mechanical fasteners such as rivets screws nuts or pins represent the most common joining elements. More often than not that means turning to adhesives.

With their quality heat resistance and bonding abilities to a wide range of plastics including PP PE PET and PV the SuperTAC 500 outperforms many other plastic bonding glue sticks. Loctite Design Guide for Bonding Plastics. The Infinity SuperTAC 500 Plastic Bonding Glue Sticks are one of the best plastic bonding hot melt options.

Henkel Corporation Rocky Hill CN has updated and reintroduced its Loctite Design Guide for bonding plastics to simplify the challenge of determining the most effective adhesiveplastic bonding combinations. To work effectively with plastics manufacturers must be able to efficiently and permanently join plastic components into complete assemblies. How To Use The Plastic BondingGuide Chapters 3.

Always handle parts with gloves as skin oils can lead to line failures. DN Staff Jan 22 2001. How To Use The Adhesive Shear Strength Table 5.

To-bond plastics and rubbers together or in combination with metals andor composites. Dont feel too bad if you dont know much about bonding plastics. Choosing which type of adhesive is appropriate for a manufacturing system depends.

Even products which appear to be composed. Note from the stress distribution curve for cleavage and peel that these bonds do not resist stress very well. Needle Bonding Design Guide 3 Overview The Issue Adhesives are universally used for bonding cannulae to hubs in needle assemblies.

Some adhesives will cause amorphous see through plastics to haze and crack. In bonding plastic feathers and nocks onto arrow shafts 3M Scotch-Weld Industrial Plastic Adhesive 4475 dries quickly to a firm bond that resists plasticizers and water. 2Five replicates of each assembly were tested.

Epoxies cyanoacrylates and methyl methacrylates. Lets take a look at each method in more detail. PLEXUS GUIDE TO BONDING PLASTICS COMPOSITES AND METALS CONTENTS Section.

We recommend that you avoid fast-cure adhesives which are more likely to crack during the 24-hour cure period. Adhesive permanently bonds difficult-to-bond plastics and rubbers together or in combination with metals andor composites. The products cost effective price per pound also.

Adhesive Performance Summarizes the results of the adhesive shear strength evaluation table. The Loctite Design Guide for Bonding Plastics Volume 6. Bonding Plastics 101.

2 The LOCTITE Design Guide for Bonding Metals Volume 6 The LOCTITE Design Guide for Bonding Metals Volume 6 3 LOCTITE Adhesive Overlap Weld 14 Nut Bolt Pop Rivets 0 Double-sided Tape 500 1000 1500 2000 2500 3500 4000 4500 Shear Stress lbf 3000 144 252 220 385 260 Advantages of LOCTITE Structural Adhesives vs.

Loctite Plastics Bonding System

Structural Bonding Alternatives For Plastics Plastics Decorating

Stick To It A Guide To The Best Glue For Plastic Plastic Glue Best Glue Glue

Structural Bonding Alternatives For Plastics Plastics Decorating

.jpg)

A Designers Guide On Development Of Advanced Medical Adhesives

Don T Glue Anything Without This Handy Reference Chart Make Reference Chart Adhesives Glue

0 comments

Post a Comment